Are you looking for high-quality PE films?

Then you have come to the right place.

Krus knows its way around PE films.

We have a large assortment of products you can choose from.

We can offer you flat and tubular films, as well as bags and films for covering.

Our products can be printed or colored according to your wishes.

Contact our competent customer advisors and find the right PE film for you and your project!

Send Inquiry

| Category | Films |

| Material | LDPE, HDPE, MDPE |

| Types | Sleeve and/or overlaps, Half-sleeve, Tape |

| Width | from 60 mm to 2100 mm (LDPE), from 190 mm to 2100 mm (MDPE), from 220 mm to 970 mm (HDPE) |

| Thickness | from 13 μm to 200 μm (LDPE), from 13 μm to 200* μm (MDPE, HDPE) |

| Color | In accordance with customer requirements |

| Flexographic printing of up to 8 colors according to pantone | |

| Properties | The strength of 15 μm LDPE is inferior to that of HDPE with the same thickness. LDPE is a more stretchable film compared to HDPE; it is more flexible and resistant to tearing. Both types of film have a high resistance to low temperatures, with HDPE performing better than LDPE in that regard. |

| Additives | Can be manufactured with certain additives: - UV additive to protect the film from the effects of sunlight - antistatic additive to protect against discharges - slip-enhancing additive for easier packaging or opening - slip-reducing additive to allow easier stacking of products on pallets - additive to facilitate heat shrink (not applicable for HDPE and MDPE) - optional perforation - optional ionization: single-sided, double-sided or segmented - in case of a film intended for printing and lamination |

| Usage | Wide range of applications in packaging, food, medical and hygiene industries |

PE films have become an indispensable part of our lives. PE stands for polyethylene, which is a thermoplastic material. PE contains neither plasticizers nor heavy metals and is therefore considered environmentally friendly. PE films protect items from damage and keep them safe from dust and moisture.

Food can be wrapped in PE film without any issues. With PE plastic bags, you don’t need to worry about contamination with toxins polluting the product.

Polyethylene film can be cut to any size, which is one of the reasons why it’s so popular. Polyethylene is cost-effective, toxin-free, and versatile. Below are some examples of uses for PE film:

Flat films, semi-tubular films, tubular films, and gusseted films all can be used to package a wide variety of goods. Whether you want to store, sell, or transport products, we can offer you the right roll of film at a reasonable price. Packaging films are also suitable for freezing.

If you work in the construction industry, then you know how indispensable films can be. Covering films are also used in agriculture, the event industry, and horticulture. If you are in the industrial warehousing sector, you should know that our films can also come with UV protection.

As mentioned above, PE films are free of harmful substances and plasticizers, meaning they are particularly suitable for use in the food sector. Shrink film keeps fruits and vegetables fresh, and due to its transparency, the customer can inspect the goods without removing the film.

The properties of the material differ slightly depending on the density. The lower the density, the more flexible the film.

We can distinguish a few types of materials: LDPE, LLDPE, HDPE, and MDPE. LLPE stands for Linear Low-Density Polyethylene and is very stretchable and impact resistant. In contrast, HDPE (High-Density Polyethylene) is particularly stable.

The material MDPE (Medium Density Polyethylene) is a middle ground between LDPE and HDPE. If you are now wondering which material is best suited for your purpose, we will be happy to advise you in this regard.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryWe supply the films mentioned below on a roll.

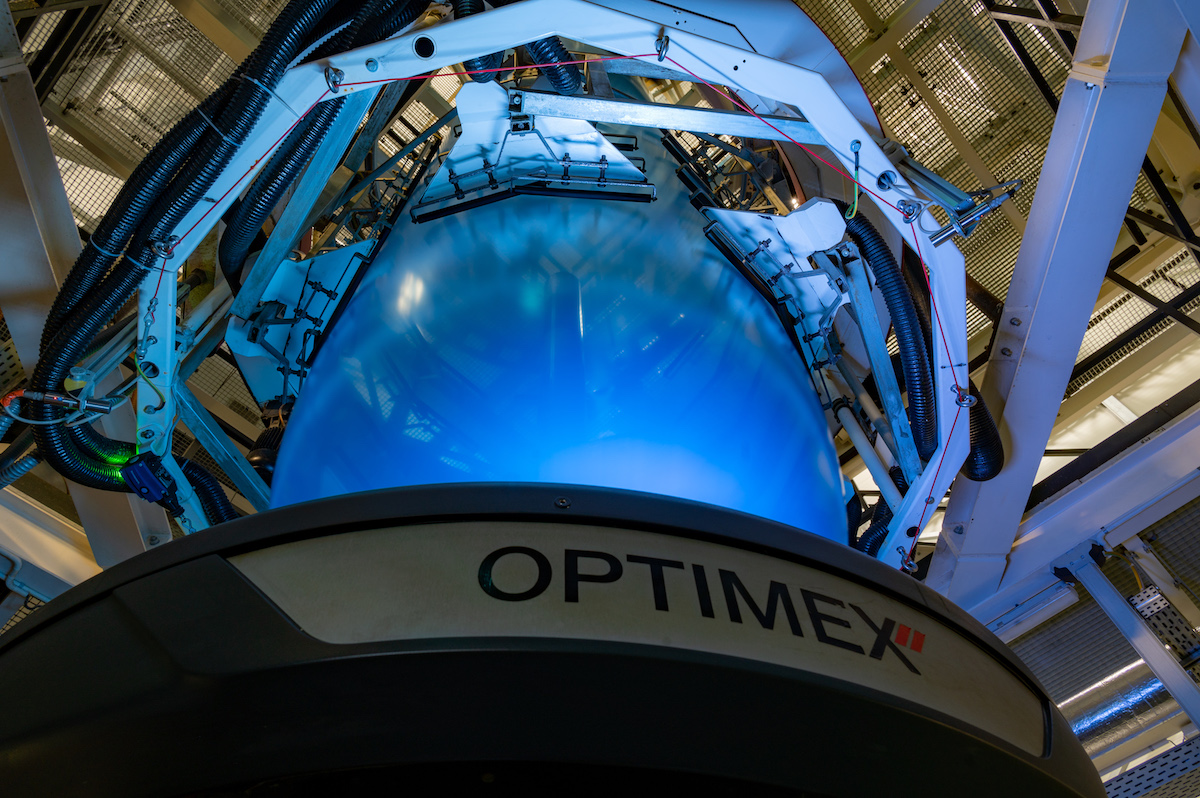

You can easily weld this film into bags. It is produced by blown film extrusion, where the polyethylene is blown out of the machine and remains in a closed tube. You can choose between different widths.

This is a tubular film that is cut open on one side. The easiest way to process these films is by using a machine.

If you cut a tubular film on both sides, you will get a single-layer flat film. You can choose between different thicknesses and dimensions.

You can order perforated or non-perforated films from us to protect your products.

You can have your film printed and use it as an advertising space. The possibilities are almost endless when it comes to printing.

Dyeing the films is not a problem either. There are many colors available, but most commonly, PE films are colored black, gray, brown, green, blue, and red.

Recycled films are the most suitable choice for the construction industry. They are particularly cost-effective.

No, PE films are not toxic. They do not contain plasticizers or heavy metals and are very suitable for food packaging.

Yes, a PE film is waterproof and very robust at the same time.

If you manage to damage the film with your fingernail, then it is PE or PP film. The difference between PE and PP is hardness – PE material is softer.

Yes, it is possible. However, you need a special adhesive to glue PE film. There are hot glue sticks and also 2-component adhesives that can glue PE films. The surface of polyethylene can not be dissolved, so gluing is hard and only possible with special adhesives.

Polyethylene (PE) is most commonly used for film production. PVC is more resistant to acids, bases, oils, and alcohol, but is used in the non-food sector. On the other hand, a PE film is very suitable for use in food packaging.

HDPE has the code number 2 and LDPE has the number 4.

Yes, PE is frost resistant when used in the manufacture of rain barrels, for example. However, to make sure that there are no cracks in the material, you should empty half of the water from the rain barrel at the onset of winter.

PE films are not resistant to UV radiation. An exception to the rule is a black-colored PE film.

All PE materials are combustible.

Polyethylene can be recycled, but care must be taken that it has not been bonded with other plastics. PE is usually recycled with the same function – i.e. an old film becomes a new one.

Polyethylene is a soft plastic that melts at high temperatures. The denser HDPE melts at 125°C and the less dense LDPE at 105°C.

Bottles, bags, and other packaging made of polyethylene can be sent over to the recycling system via the yellow bags and yellow garbage cans.