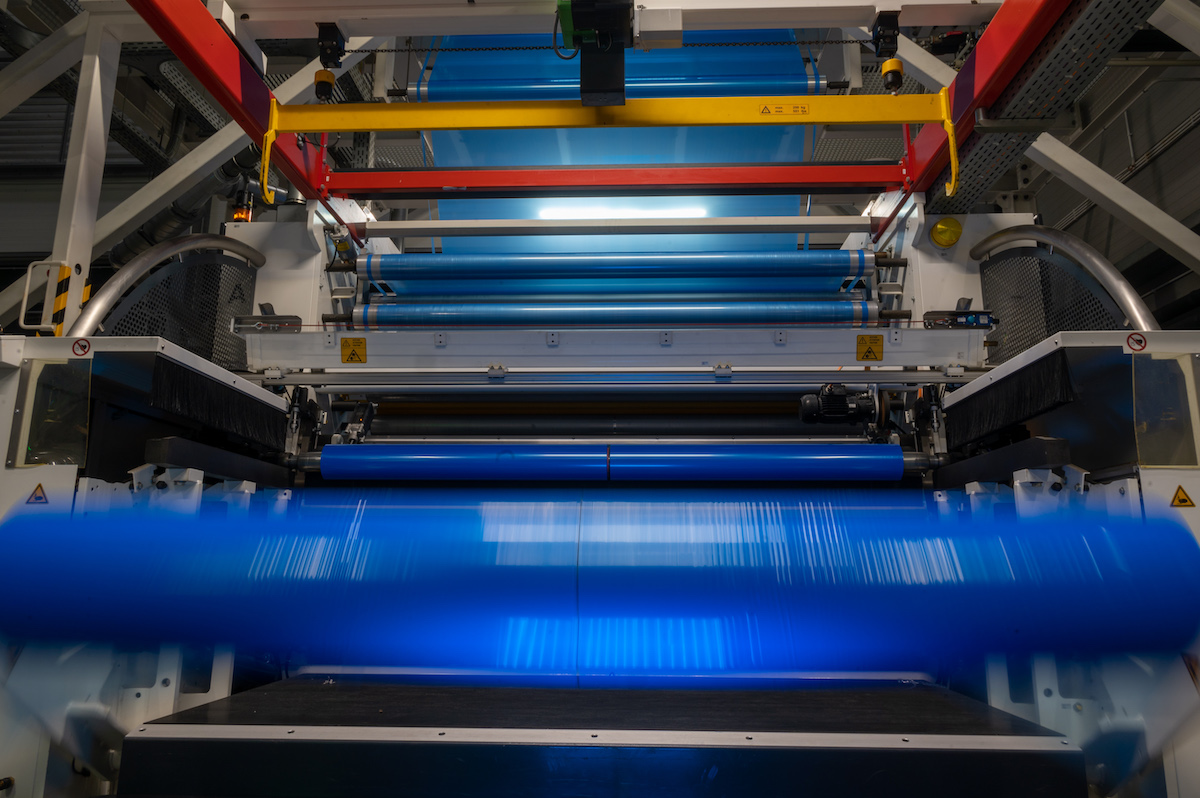

Shrink film can be used to protect items from dust and tampering, as well as form six-packs or multi-packs.

This type of film is designed to shrink when heated.

This method is used, for example, to prevent DVD cases from being opened in stores.

Other films can be made differently if you don’t want the film shrunk tightly around your product (i.e., you prefer to loosely bag or vacuum pack your product).

Polyethylene shrink film is an extremely durable and versatile “premium” film.

It is a food-safe material that has been used in lieu of PVC in many areas.

Send Inquiry

| Category | Films |

| Material | LDPE, HDPE, MDPE |

| Types | Sleeve and/or overlaps, Half-sleeve, Tape |

| Width | from 60 mm to 2100 mm (LDPE), from 190 mm to 2100 mm (MDPE), from 220 mm to 970 mm (HDPE) |

| Thickness | from 13 μm to 200 μm (LDPE), from 13 μm to 200* μm (MDPE, HDPE) |

| Color | In accordance with customer requirements |

| Flexographic printing of up to 8 colors according to pantone | |

| Properties | The strength of 15 μm LDPE is inferior to that of HDPE with the same thickness. LDPE is a more stretchable film compared to HDPE; it is more flexible and resistant to tearing. Both types of film have a high resistance to low temperatures, with HDPE performing better than LDPE in that regard. |

| Additives | Can be manufactured with certain additives: - UV additive to protect the film from the effects of sunlight - antistatic additive to protect against discharges - slip-enhancing additive for easier packaging or opening - slip-reducing additive to allow easier stacking of products on pallets - additive to facilitate heat shrink (not applicable for HDPE and MDPE) - optional perforation - optional ionization: single-sided, double-sided or segmented - in case of a film intended for printing and lamination |

| Usage | Wide range of applications in packaging, food, medical and hygiene industries |

Polyethylene materials are available with a variety of properties, including a cross-linked film that offers high tensile strength and incredible clarity for high-speed packaging applications. The film also prevents deposits on the sealing components of machinery.

Not all shrink films are created equal when it comes to packaging food – polyethylene is the clear winner here. At Krus, we’ve been selling shrink films for a long time and have a perfect understanding of the best applications for each type of shrink film.

Packaging is always about safety first and foremost. While there are several types of shrink film, not all of them are suitable for food packaging. Polyethylene shrink film is undoubtedly the best choice for food packaging.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryThe most important advantages of using polyolefin shrink film for food packaging include:

Polyethylene shrink film is a high-quality product that is a great choice due to its wide range of applications. PVC shrink films contain phthalates, which make the material unsafe for food packaging. When using PVC for wrapping food, special care must be taken to select the right composition. This is due to the limited temperature and water vapor permeability rates of PVC.

On the other hand, polyethylene shrink film has the perfect choice for food safety, stretchability, and clarity.

Polyethylene shrink film has extremely high transparency for applications that can benefit from the visual appeal. Polyethylene retains its clarity for up to one year after manufacture. It can be relied upon to maintain the visual impact and gloss that people have come to expect from foods packaged in this material.

In other words, this type of film has an amazing shelf appeal.

The glossy and transparent properties of polyethylene shrink film make it the perfect choice for food presentation. Whether you’re packaging meat, vegetables, or virtually any other type of food, you can be sure it will catch the eye of picky consumers as they browse through the shelves.

Many people don’t know that polyethylene shrink film can be recycled. Its unique molecular formula makes it a fully recyclable product, with some companies even willing to pay you to bundle and recycle your used shrink wrap! This means polyethylene can offer a higher ROI and lower environmental impact for your business.

Thanks to its chemical composition, this type of polyethylene film shrinks quickly and evenly as it passes through the heat tunnel. By using polyethylene shrink film in your packaging line, you are able to save time and package your products more evenly.

Polyethylene shrink film is a flexible and durable material that can handle delicate foods like crackers and other items with rough edges. Whether you’re packaging frozen pizzas, pies, or loaves of bread, you can be sure that your product will be well protected inside. This helps establish your brand as reliable and consistent. A good experience means customers know what they’re getting and are happy to come back.

Polyethylene shrink film can be used to package and protect thousands of different foods. This film is used for many types of edibles, from sliced bread and baked goods to meat, fish, poultry, and virtually everything in between. If you’re packaging food, polyethylene is usually an excellent choice for your products.

Polyethylene shrink film is not only a durable and versatile material, but it’s also very economical.

Unitization is the art of bundling products together for shipping and shelf appeal. To illustrate the point, it is common to find items such as tissue boxes and toilet paper rolls bundled in shrink wrap. This is a common application for polyethylene shrink film that can help your products stand out more.

Compared to other types of shrink film, polyethylene shrink films are more resistant to temperature fluctuations and temporary exposure to extreme temperatures.

Polyethylene shrink film features excellent tear resistance and higher tensile strength than other shrink film materials. As such, it is a better choice for packaging food products with corners or uneven shapes.

Perforated polyethylene shrink film can reduce the formation of air pockets and create a smooth and uniform shrink surface.