Do you want to package your goods in a cost-effective and environmentally-friendly way?

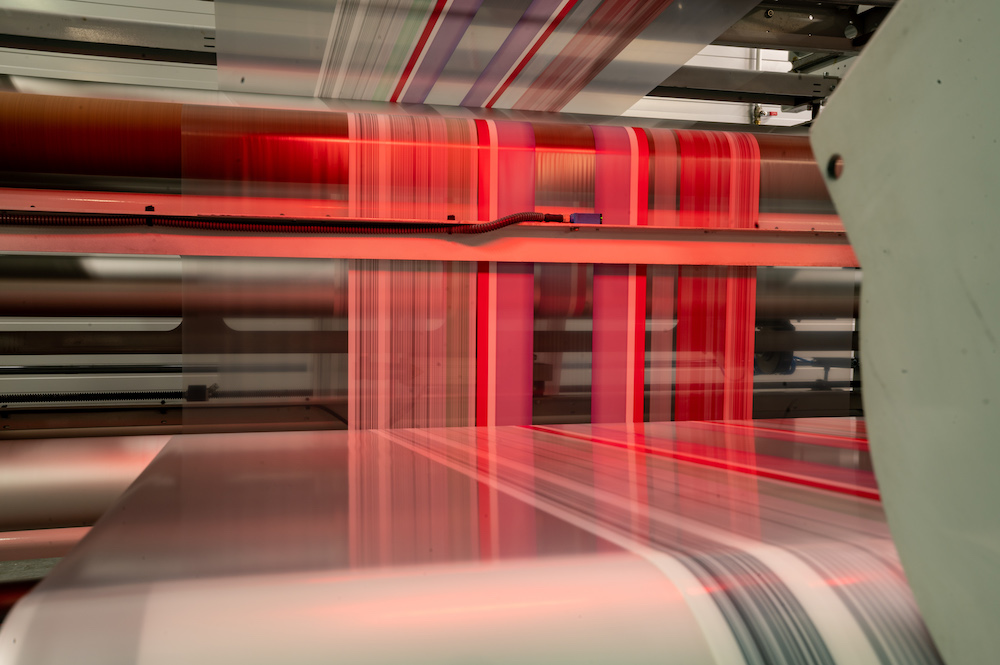

It won’t be a problem with flow pack films for packaging machines.

These are produced by Krus in a wide variety of designs – always according to the wishes of our customers.

Our films offer airtight packaging and protect your goods from external influences.

In the following text, we will go into more detail about the properties and applications of this product.

If you have any additional questions, make sure to contact us – we will be happy to help you!

Send Inquiry

| Category | Films |

| Material | |

| Types | |

| Width | |

| Thickness | |

| Color | |

| Properties | |

| Additives | |

| Usage |

Flow pack films are used to store goods in an airtight manner.

The packaging process is carried out mechanically with the aid of a tubular film that is sealed at the beginning and at the end.

This way, a wide variety of goods can be packaged, ranging from candies or detergent tabs, but also other foodstuffs, such as minced meat and vegetables.

Flow pack films are manufactured by the Krus company from LDPE.

There is no need to worry about using this material, as it is not harmful and does not introduce any foreign smells to packed goods and products.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryPlastics are ideally suited to protect the countless goods of today from dust, dirt, moisture and other elements.

You already knew that? Not surprising – after all, we encounter various types of plastic packaging almost every day in the form of canisters, bottles, and food packaging.

However, not all plastics are the same, so there are a few points to consider when choosing the correct material for your needs.

A big advantage of LDPE (Low-density Polyethylene) is its softness, making it easy to shape and process.

Moreover, polyethylene (PE) plastics are so popular because they are entirely food safe, as LDPE doesn’t contain BPA and hence is not overly harmful to the natural environment.

No, there is no minimum order quantity for this product. How much you buy depends only on your personal needs.

Of course. Depending on the required packaging properties, we can offer you the following additives:

Definitely! That’s what flow packs are used for: professional, hygienic packaging of food products! The material we use for production is not harmful, nor does it change the smell or taste of your edible goods. It is 100% food safe.

Interestingly, the material used, LDPE, is particularly resistant to punctures, so there is no need to worry about damage to the wrapping itself.

Yes, it is possible. We produce knurled, punched, needled, and perforated films for packaging machines. All designs have different properties. We will be happy to consult with you to determine the version that’s suitable for your products for your packaging needs.

Here is a brief overview:

Knurled films for packaging machines:

Through the process of knurling, we can make our films more grippy.

Punched films for packaging machines:

Punched films provide a very good airflow to wrapped goods, which is mandatory for certain food products.

Needled film for packaging machines:

This type of film is perforated by very fine needling, which makes it suitable for packaging bread or rolls, for example. The needling prevents excessive condensation from forming.

Perforated films for packaging machines:

Just like punched and needled films, perforated packaging also allows for a very good airflow. If you want your goods, such as baguettes, to stay crispy for a long time, you will do very well with this film variant.

No – the flow packs or films for packaging machines are made of plastic. As such, end users can simply dispose of the used packaging in their household waste bins.

Yes! Used flow packs can be recycled again after being disposed of. For you and your end users, this means no additional expense, as you simply have to throw the packaging away into the yellow bags or yellow garbage cans.