Do you want to easily package your medical products and protect them from microorganisms according to the highest possible standards?

If so, you may have just found what you are looking for!

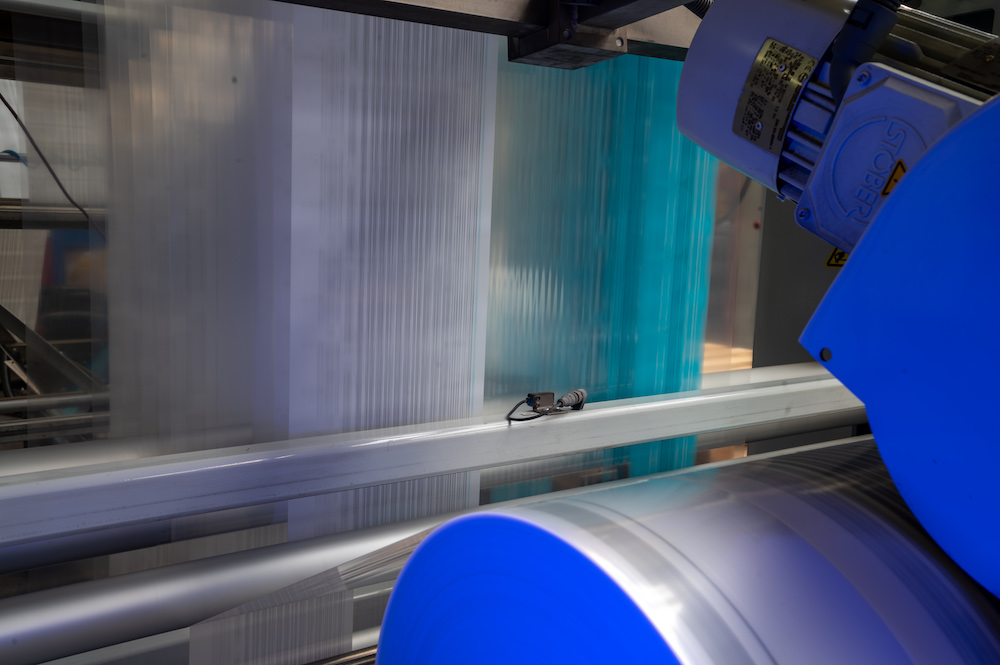

Our company produces films in different variations, including flat, tubular, and semi-tubular films, which can be purchased as hoods, bags, carrier bags, sacks, or blanks.

We already supply a large number of customers in the medical sector.

Below, we will introduce our antibacterial products in detail.

If you have any additional questions, we are always available for a personal consultation – at any time!

Send Inquiry

| Category | Films |

| Material | |

| Types | |

| Width | |

| Thickness | |

| Color | |

| Properties | |

| Additives | |

| Usage |

LDPE is a material that we use on a daily basis. It is important for the production of a wide variety of films, packaging, and bags and was the first polyethylene grade to be produced worldwide. The abbreviation LDPE stands for Low-density Polyethylene.

Due to a large number of side branches, LDPE is also extremely tear-resistant and thus very well suited for the production of packaging. It is also temperature resistant – LDPE only begins to melt at 105°.

We offer our customers antibacterial films as flat films, tubular films, and semi-tubular films, which can take the shape of finished hoods, bags, carrier bags, sacks, or blanks in the further production process.

A flat film, just like its name suggests, is a flat, single-layer film used as packaging or covering to protect goods and products.

A tubular film is a product that can be made as a real tube without seams by a special manufacturing process. With the aid of a film sealing device, it is possible to extract the air after packaging in order to vacuum seal products when necessary.

A semi-tubular film refers to a PE film that is open on one side. The film is usually further processed or sealed in a packaging machine, such as an automatic angle sealer.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryAntibacterial films provide effective and proven protection against pathogens, which makes them irreplaceable in the medical sector for packaging goods such as instruments and products.

In principle, however, antibacterial films are also relevant for other places with high hygiene requirements (e.g., in the food industry, public areas, and others).

LDPE film is produced from granules supplemented with substances that inhibit the spread of bacteria.

In other words, it is possible to create films with bacteriostatic and bactericidal properties.

Additional vacuum sealing of the package further protects your goods against environmental elements such as dust, dirt, etc.

In principle, we base the order quantity on the wishes of our customers. However, the minimum order size for the antibacterial films needs to be at least 600 kg. If you have any questions, please contact us to learn more and get further details.

You can purchase antibacterial films from us as finished bags, hoods, or carrier bags, as well as in the form of blanks. These are already processed so that they can be immediately used by your company. We will be happy to help you choose the right design for your products and goods!

If your products cause electrostatic charging of the packaging film, we can recommend choosing an antistatic agent as an additive. This material is mixed in with the plastic granulate during the production of the film and helps minimize the risk of electrostatic charging.

We offer a number of different additives to our customers, including UV stabilizers (to protect the goods from UV radiation), as well as antiblock and antifog additives (to prevent the bags or films from sticking and fogging, respectively).

Our antibacterial films also have the capability to protect your goods from moisture and humidity. As already mentioned above, further additives such as UV stabilizers can be mixed in to help protect your good from other harmful influences (e.g., solar radiation).

Yes – we have developed a very successful flexographic printing method and offer our customers the possibility to choose between 8 high-quality Pantone® colors for their designs.

The disposal of films and film packaging is very clearly regulated in Germany. This means that there is no additional expense for you or the end user. You can simply put the used bags in the yellow garbage cans or the yellow bags – it will add them back to the recycling cycle.

No, LDPE films are food safe and are not classified as harmful. LDPE was the first polyethylene to be developed and has been used worldwide since 1933. In other words, LDPE is a very well-proven material.