Flexography is a printing process that uses a flexible printing plate to transfer ink to an item—typically a plastic, glass, or metal container. Flexo printing is used for packaging, labels and tags, and other items that are large enough to accommodate the large printing plates used in flexography.

Packaging, such as boxes and cans, labels and tags, food, beverage, and pharmaceutical containers, household cleaning products, and magazines, can all be printed using flexography. The process is popular for its high-quality printing, durability, and fast turnover times. Flexography is also referred to as flexo or PL (photopolymer).

Below, we’ll take a quick look at what flexography is, how it works, and why it matters in the packaging industry.

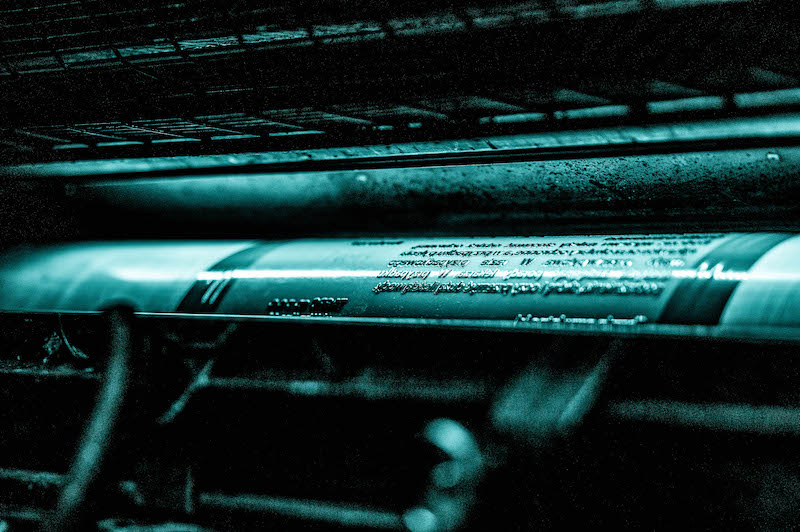

As we mentioned above, flexography uses a printing plate to transfer ink to a surface. The plate is made of a flexible material, such as vinyl or rubber, and has high-contrast images of the object to be printed on it.

In the printing press, ink is applied to the plate, and it is then inked up. As the plate is pulled through the press, it transfers ink to the item being printed, which is moved beneath it. In order to transfer an image from the plate to the item, the ink must be transferred from the plate to the item. This process is called “registration” and occurs when the ink from the plate makes contact with the item at the same time that pressure is applied to the item.

The plates are inked using a flexo platen press. It is typically applied for large-scale items, such as boxes and cans, but it can also work for smaller items, such as labels and tags.

One of the most important aspects of flexography is plate preparation. Printing plates are made of materials that do not distort under pressure and can withstand high temperatures. Plates have a clear top coat to keep them clean during production. The ink is held onto the plates by an adhesive, and the plates are heated to ensure proper adhesion of ink and protection from solvents in ink.

Once plates have been made, they are cleaned with a solution that removes waxes and oils from the plate’s surface. This step ensures that the ink will adhere to the surface properly. Next, plates are used in flexographic printing presses—typically rotary presses—to print products.

Flexography is a high-quality printing process. Because it allows for high-resolution images, flexo can be used to print detailed images on products. It is also perfect for printing full-color graphics, and its durable nature makes it ideal for packaging. It allows for fast production times and complete customization.

One of the biggest benefits of flexography is that it is cost-effective. The plates used in the process are reusable, so they can be applied to multiple prints. Also, the application of pressure means more efficient use of ink, which reduces costs.

In addition to the cost savings, flexography can work with a variety of product types and sizes. The printing plates make the process able to handle larger orders and provide flexibility in the type of items that can be printed. The process is also ideal for printing small things, such as tags and labels, as well as individual items.

Another benefit of flexography is that it can be applied quickly. This process enables shorter turnaround times than other printing processes. Due to its versatility, flexography can be applied for short-run and large-run projects alike. Flexography can also work with various product types, from bottles to boxes, allowing for easy customization.

Flexography is a high-quality printing process. Because it allows for high-resolution images, flexo can be used to print detailed images on products. It is also perfect for printing full-color graphics, and its durable nature makes it ideal for packaging. It allows for fast production times and complete customization.

One potential drawback of flexography is that it requires a large initial investment. The plates used in the process are expensive, and the presses required to print products can also be costly. In addition, because it is a printing process that uses pressure, there is a risk of damaging delicate items. That’s why it might be a good idea to work with a professional printing company that has experience with flexography.

Flexography is a versatile printing process that can be used on a variety of materials, from glass to metal to plastic. It’s perfect for projects that require high-quality images and graphics, as well as durability. If you’re unsure whether flexography is the right printing process for your project, we recommend working with a professional printing company that has experience with the process.

Flexography can be used to print packaging, labels and tags, food, beverage, and pharmaceutical containers, household cleaning products, and magazines.