Krus films protect your goods from damage, moisture, and dirt.

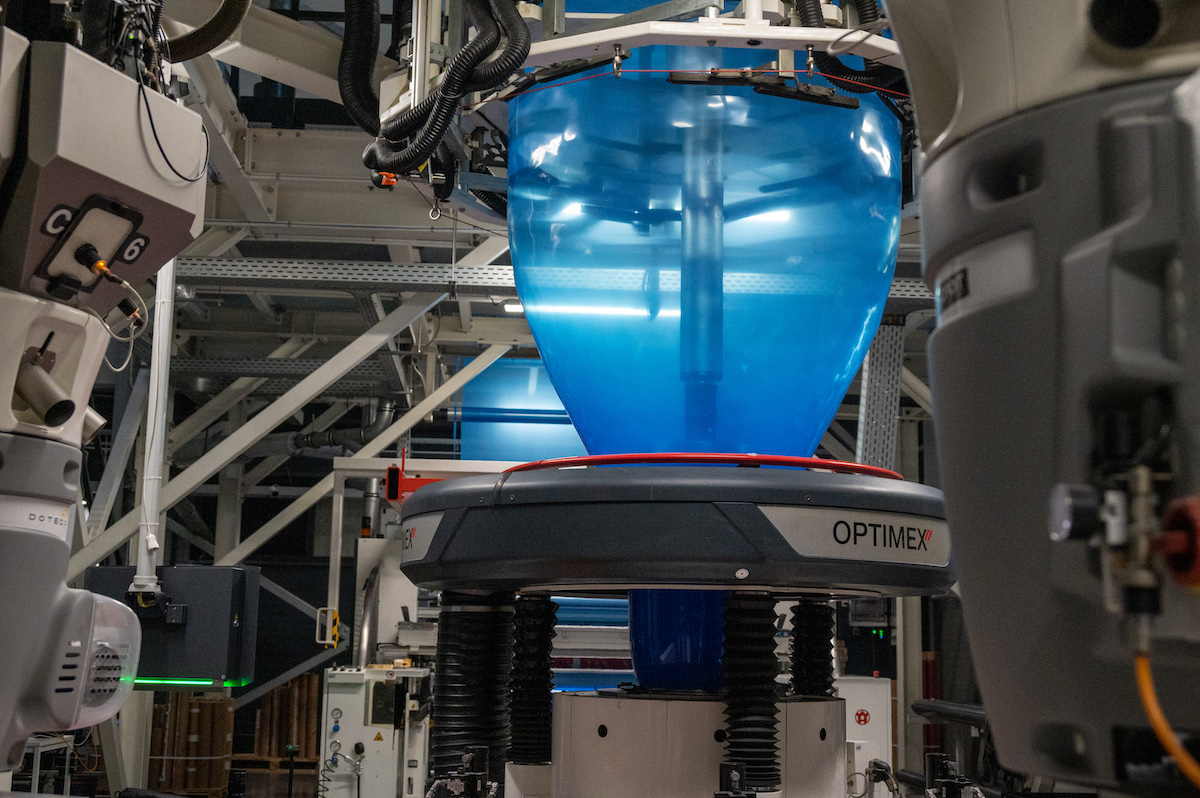

You decide whether you need a sleeve or a cover. LDPE is a flexible material that can be extremely helpful.

The high transparency of the low-density PE film ensures that the products packed in it are easily visible.

We can manufacture LDPE industrial films and film packaging for you. Contact our competent staff for detailed information.

If you need large quantities but do not have storage space for it, ask us: we can take care of storage and picking for you.

LDPE is used to produce the flat film, tubular film, and semi-tubular film. If you tell us which packaging machine you use we will make you a suitable offer.

Whether you pack pears or need LDPE because of its water-repellent properties – we will be happy to advise you.

Send Inquiry

| Material | LDPE |

| Types | Sleeve and/or overlaps, Half-sleeve, Tape |

| Width | from 60 mm to 2100 mm |

| Thickness | from 13 μm to 200 μm |

| Color | In accordance with customer requirements |

| Flexographic printing of up to 8 colors according to pantone | |

| Properties | The strength of 15 μm LDPE is inferior to that of HDPE with the same thickness. Compared to HDPE, LDPE is more stretchable, flexible, and more resistant to tearing. However, LDPE is not suitable for use with heavier items. Both types of film have a high resistance to low temperatures. Films made of original raw materials are always transparent, but can be mixed with a suitable dye. LDPE does not affect the properties of the products with which it comes into contact. Regranulate films offer less transparency depending on the type of regranulate: post-production (grade I), straw-type regranulate and MIX regranulate. |

| Additives | Can be manufactured with certain additives: - UV additive to protect the film from the effects of sunlight - antistatic additive to protect against discharges - slip-enhancing additive for easier packaging or opening - slip-reducing additive to allow easier stacking of products on pallets - additive to facilitate heat shrink (not applicable for HDPE and MDPE) - optional perforation - optional ionization: single-sided, double-sided or segmented - in case of a film intended for printing and lamination |

| Usage | Packaging industry; production of garbage, string, and reusable bags, packaging for textiles, newspapers, as well as the construction industry. Widely used in transportation industry, horticulture and food sector to package fresh and frozen food. |

Low-density PE film is the ideal packaging film. It can be used flexibly and is very popular for packing fruits and vegetables due to its optimal transparency.

The special properties of the material make LDPE the most popular film.

These are the words that define the LDPE. If you process, store, or transport products, you can rely on this film. The applications of LDPE are very diverse, with many industries using this film. Whether you are shipping books, covering construction materials, or packaging pears, LDPE is the ideal solution.

In addition to the basic film, we offer colored films. We can also equip LDPE films with a UV stabilizer so that your goods are protected from the sun’s UV rays. At Krus, you can get shrink films, tubular films, flat films, and semi-tubular films made of LDPE. But we can also convert your product and offer you ready-made bags and pouches.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryLDPE is also called PE-LD. The abbreviation stands for Low-Density Polyethylene. Low-Density Polyethylene is also called soft polyethylene. Polyethylene, like other types of plastic, is made from petroleum and is a waste product of the petrochemical industry.

The second ‘L’ you may sometimes see before LDPE stands for linear (LLDPE: Linear Low-Density Polyethylene). LLDPE film is puncture resistant and flexible. HDPE film (High-Density Polyethylene film) and MDPE film are other subtypes of PE film. The most transparent of all PE films is the LDPE film. If you do not know which film is the most suitable for your project, please contact us. We will be glad to advise you.

LDPE film is:

We supply the films mentioned below on the roll.

LDPE film can be colored like any PE film. You can choose from black, gray, brown, green, blue and red. We can also apply an advertising print.

No, PE films are not toxic. They do not contain plasticizers and heavy metals and are very suitable for food packaging.

Yes, the PE film is waterproof and also very robust.

PE or PP films can be damaged with a fingernail. The difference between PE and PP is softness, with PE being softer.

Yes, it is possible. However, you need a special adhesive to glue PE film. There are hot glue sticks and also 2-component adhesives that can glue PE films. The surface of polyethylene cannot be dissolved, so gluing is possible only with special adhesives.

Polyethylene (PE) is most commonly used for film production. PVC is more resistant to acids, bases, oil, and alcohol. PVC is not used in the food sector, while PE film is very suitable for use in food packaging.

HDPE carries the code number 2 and LDPE the number 4.

Yes, PE is frost resistant when used in the manufacture of rain barrels, for example. However, to make sure that there are no cracks in the material, you should empty half of the water from the rain barrel at the onset of winter.

PE films are not resistant to UV radiation. An exception to the rule is the black-colored PE film.

All PE materials are flammable.

Polyethylene can be recycled, but care must be taken to ensure that it has not been bonded with other plastics. PE is usually recycled to perform the same function – i.e., an old film is recycled to become a film again.

Polyethylene is a soft plastic that melts at high temperatures. The denser HDPE melts at 125°C, and the less dense LDPE at 105°C.

Bottles, bags, and other packaging made of polyethylene can be sent to the recycling system via the yellow bags and garbage cans.