Krus films protect your goods from damage, moisture, and dirt.

You decide whether you need a sleeve or a wrapping. HDPE is a tear-resistant material that provides great value.

This film is also highly resistant to scratches and can withstand extensive wear. Due to the low-pressure manufacturing process, even very thin HDPE films can prove a durable packaging material, meeting your strict requirements.

HDPE is not only used to produce flat films, tubular films, and semi-tubular films; you can also order blanks and bags from us.

Tell us which type of packaging machines you use, and we will adjust our offer accordingly. Let our qualified staff help you choose the right film for your products.

If you need large quantities but do not have enough storage space, send an inquiry. We can take care of storage and deliver it to you when needed.

Send Inquiry

| Category | Films |

| Material | HDPE |

| Types | Sleeve and/or overlaps, Half-sleeve, Tape |

| Width | from 190 mm to 2100 mm |

| Thickness | from 13 μm to 200* μm |

| Color | In accordance with customer requirements |

| Flexographic printing of up to 8 colors according to pantone | |

| Properties | MDPE has a significant mechanical strength, higher than LDPE. On the other hand, MDPE is not as transparent as LDPE. MDPE is also more flexible than LDPE, but not as rigid as HDPE. |

| Additives | Can be manufactured with certain additives: - UV additive to protect the film from the effects of sunlight - antistatic additive to protect against discharges - slip-enhancing additive for easier packaging or opening - slip-reducing additive to allow easier stacking of products on pallets - additive to facilitate heat shrink (not applicable for HDPE and MDPE) - optional perforation - optional ionization: single-sided, double-sided or segmented - in case of a film intended for printing and lamination |

| Usage | - packaging of fresh and frozen foods - packaging of industrial products |

High-density PE film is the perfect packaging film if you need strength and durability. Our HDPE foil shows high resistance to wear and external forces, and is difficult to tear. The only downside is that it is not as flexible and transparent as our LDPE foil.

HDPE’s special properties make it a cost-effective material. Its characteristics include:

HDPE is a versatile film that can be used in many industries. It is strong and durable, making it ideal for shipping and storing products such as books or construction materials. HDPE is also lightweight, making it ideal for covering construction sites or making tote bags.

In addition to the basic film, we offer colored films, which can also be equipped with a UV stabilizer so that your goods remain protected from the sun’s UV rays. At Krus, you can get tubular films, flat films, and half-tubular films made of HDPE, but we can also work around your product and offer you ready-made bags and pouches.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryHDPE is also called PE-HD. The abbreviation stands for High-Density Polyethylene. Polyethylene, like other plastic sheets, is made from petroleum and is a by-product of the petrochemical industry.

Krus offers other types of films: LDPE, LLDPE, and MDPE film. LDPE stands for Low-Density Polyethylene, a more flexible and puncture-resistant form of PE film. LLDPE is a cross-linked form of LDPE that is used for high-performance applications. MDPE, on the other hand, is used for applications that require both durability and flexibility. If you don’t know which film is best for your project, feel free to contact us. We will be glad to assist you.

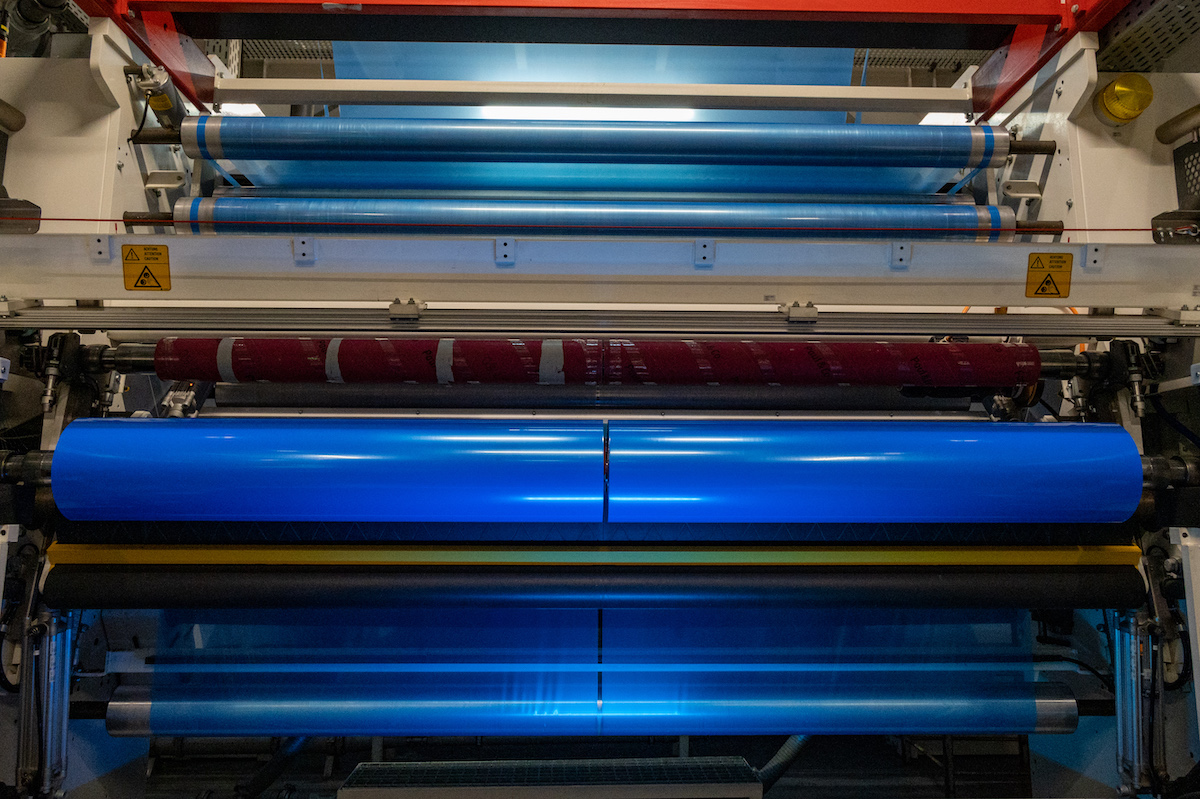

Krus manufactures tubular, semi-tubular, and flat HDPE films. Each type is produced in the process of blown film extrusion, where the polyethylene is cast into a closed tube and then supplied on rolls. At Krus, you can choose between different dimensions and thicknesses matching your specific application.

HDPE can also be colored like any other PE film. You can select between black, gray, brown, green, blue, and red. We can also offer printing advertising labels, perforating, and needling of the HDPE film of your choice.

No, this film does not contain plasticizers or heavy metals. This means it is perfect for food packaging.

Yes, HDPE film is waterproof. It can also withstand exposure to acids and alcohols.

You can do the nail test. If you succeed in damaging the film with your fingernail, then it is PE or PP film. PE is softer than PP.

Yes, though you’ll need a special glue. Both hot glue sticks and 2-component glue can stick PE film.

HD polyethylene (PE) is most commonly used for film production. PVC is more resistant to acids, bases, oil, and alcohol, but is not used in food applications due to its potential toxicity. PE film, on the other hand, is very suitable for use in food packaging.

HDPE number 4 and LDPE number 2.

Yes, HDPE is frost resistant when used to manufacture rain barrels, for example. However, when winter sets in, you should empty half of the water from the rain barrel to safely avoid damage from low temperatures.

No, HDPE films are not UV resistant. Black-colored PE film is an exception.

Yes, all PE materials are flammable.

If polyethylene has not been bonded with other plastics, it can be recycled.

Polyethylene is a soft plastic that melts at high temperatures. The denser HDPE melts at 125 °C, and the less dense HDPE at 105 °C.

Bottles, bags and other packaging made of polyethylene can be handed over to the recycling cycle via the yellow bags and yellow garbage cans.