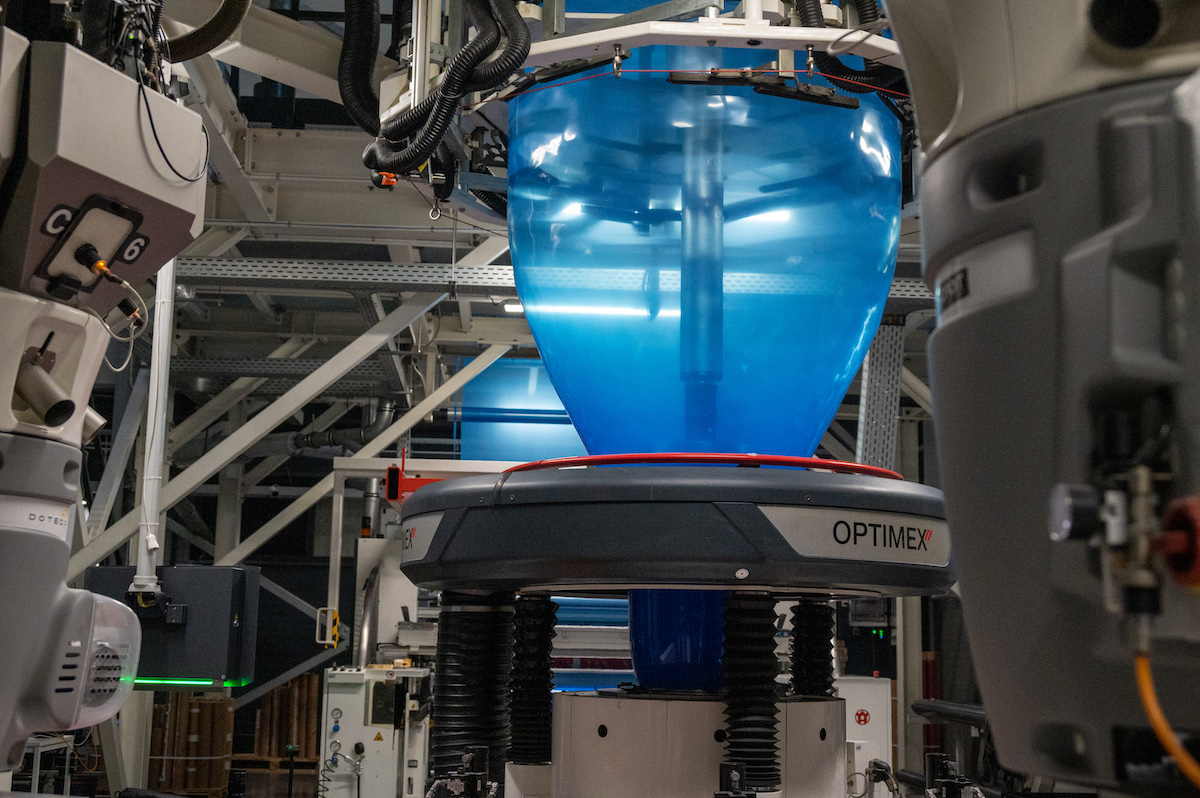

Are you looking for transparent packaging that allows you to showcase your products standing upright?

If so, you should definitely take a look at our bottom gusset bags.

Many edible goods such as chocolate, confectionery, or pastries can be aesthetically packaged, presented, and even used by your customers as gifts.

All this is possible thanks to the bottom gusset created during the production of each bag.

Send Inquiry

| Category | Bags |

| Material | LD; COEX; MDPE; REGRANULAT;PP;CPP;LAMINAT;OPP |

| Width | ab ca. 40 mm – 900 mm |

| Coloring | In accordance with customer requirements |

| Printing | Flexographic printing of up to 8 colors according to pantone |

| Additives | Antistatic, UV stabilizer, antiblock, antifog |

| Usage | Packaging industry, medical technology, construction industry, electrical industry, automotive industry, food industry, agriculture |

Our bottom gusset bags are suitable not only for food products, but are also a great choice for medical and electrical engineering items. To help you make a decision, we will take a look at the possible materials and properties of your required bags. Of course, we are also ready to advise you individually at any time, so please contact us if you have any doubts or questions!

LDPE is a thermoplastic material with low density. It has good tear resistance and is tasteless as well as odorless and oxygen-permeable. LDPE is best known for the yellow bag, which we have all used numerous times in our lives, at least before the introduction of the yellow garbage can. Besides the notable tensile strength, LDPE is also highly popular because the material is very temperature resistant (-40° to 95° Celsius).

Multilayer plastic is capable of adding different properties to a single product. Example: combining waterproof and airtight film. COEX is extremely tear-resistant.

Unlike LDPE (Low-density Polyethylene), MDPE is medium-density polyethylene. Compared to LDPE, it is more resistant to stress corrosion cracking.

Those who attach particular importance to environmental protection and sustainability can choose our products made of regranulate. Here, used and old polyethylene products are recycled into granulate and then remade into new films. The process doesn’t impact the final quality of the new products.

Polypropylene, short for PP, has a similar chemical composition to polyethylene (PE). The main difference between these two materials lies in their properties. PP is more resistant to cold and heat, as well as harder to tear.

CPP is transparent, yet very stable and highly resistant to abrasion. These properties ensure that CPP (cast polypropylene) is one of the most frequently used polymers in the film and packaging industry.

OPP (Oriented Polypropylene) is a material just as popular as CPP. Oriented polypropylene has impressive properties, including high stability and great tear resistance. In addition, the material is 100% food safe, meaning it is particularly suitable for packaging edible goods – there is no risk of food contamination or loss of valuable flavor.

Do not hesitate to contact us for more information about the different films and to find out which product is the right one for your project!

Send InquiryAre transparent film bags not enough for you? We understand that well.

As with most of our film products, we have an in-house capability to print on the bottom gusset bags.

We use a selection of 8 first-class Pantone® colors for this purpose.

If you are unsure about the right colors and designs for your needs, make sure to contact us – we will be happy to use our experience to assist you!

Bottom gusset bags are particularly suitable for goods and products that are to be transported and presented upright. A whole range of areas benefit from bottom gusset bags, including the food industry, packaging of advertising materials, as well as toys, electrical or medical technology sectors.

Like many of our products, the films used for the production of bottom gusset bags can be laced with special additives. This ensures that your goods are optimally protected against certain threats, e.g., UV radiation (UV stabilizers). Other possible additives are:

We produce bottom gusset bags in knurled, punched, needled, and perforated versions in order to best meet the needs and characteristics of your products.

We understand that the term “plastic” is a cause of concern for many interested parties when it comes to environmental protection and sustainability. However, PE and PP films are not as bad as their reputation suggests! The properties of our film bags differ from those produced from paper, among others, as follows:

High tear and impact resistance: while bags made of paper are tear and impact-resistant to a certain extent, they are not nearly as strong as bags made of film.

Temperature resistance: PP film bags can withstand temperatures from -20 to + 100° Celcius without losing their properties. That makes them superior to other film and paper products.

Low weight: Film bags are significantly lighter than paper bags.

Transparency: In contrast to paper bags, your goods are fully visible despite being completely encased in film packaging.

Finally, we would like to point out that our bottom gusset bags may be disposed of using yellow bags and/or yellow garbage cans. This way, old bottom gusset bags are added back to the cycle of recyclable materials.