Medium-density polyethylene (MDPE) is a type of plastic that has become increasingly popular in recent years, as it’s now being used for a variety of applications, including packaging, medical devices, and containers.

MDPE is a versatile material with excellent chemical resistance, making it ideal for use in many harsh environments. Additionally, it can be molded into any desired shape and size with relative ease.

This type of plastic boasts an incredibly long lifespan when properly cared for; although its low cost makes it attractive to consumers in the short term, they also benefit from its lasting durability over time.

In this article, we look closer at the properties of MDPE, its applications, and the advantages it brings to the packaging industry.

Medium-density polyethylene (MDPE) is a type of plastic made from ethylene, which is derived from natural gas or petroleum. It’s classified as an elastomeric material, meaning it can be stretched and reformed without losing its original shape.

MDPE is known for its flexibility and durability, as well as its excellent chemical resistance. This makes it ideal for use in harsh environments or areas prone to extreme temperatures. It’s also highly resistant to the effects of UV radiation, making it a popular choice for outdoor applications.

The material is lightweight yet strong enough to withstand heavy loads without cracking or breaking down. Due to its low cost and easy moldability, MDPE is a great choice for packaging, medical devices, and containers.

MDPE has also become increasingly popular as an alternative to traditional plastics in the packaging industry due to its low toxicity levels.

MDPE offers a range of benefits to the packaging industry.

The material is incredibly durable, meaning it can withstand heavy loads and be reused for a long time, so companies don’t have to invest in new packaging as often. Its low cost also makes it a great option for businesses on tight budgets.

MDPE is highly resistant to chemicals and other environmental factors, making it suitable for use in harsh conditions without the risk of damage or degradation. It’s also lightweight, so companies can transport goods more efficiently with fewer costs associated with shipping and storage.

The material’s flexibility means that it can be molded into any desired shape or size with relative ease, while its chemical resistance ensures that neither the product nor the environment will be harmed by exposure to potentially hazardous substances during transit or handling. Additionally, MDPE is less likely than traditional plastic materials to cause pollution due to its low toxicity levels.

Finally, many people are now looking towards eco-friendly solutions when choosing their packaging materials – MDPE provides an excellent alternative here, too; not only does it last longer than traditional plastics, but it’s also entirely recyclable at the end of its life cycle!

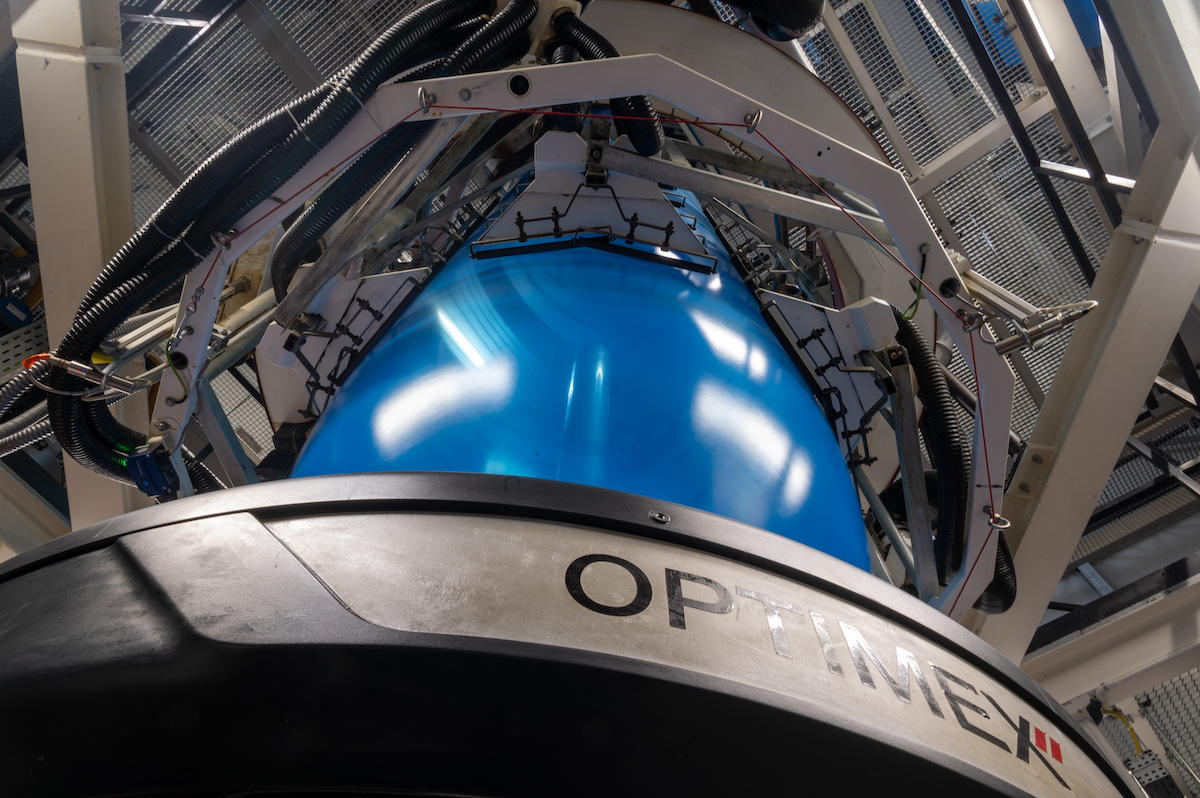

You can’t forget the fact that MDPE looks great as well; the material has a glossy, attractive finish which helps to enhance the visuals of any product.

Medium-density polyethylene (MDPE) is a versatile and highly durable material that has become increasingly popular in the packaging industry due to its low cost, chemical resistance, and flexibility. It boasts many benefits for companies looking for eco-friendly alternatives, including its long lifespan and recyclability.

Overall, MDPE provides an excellent solution for businesses wanting to reduce their costs while ensuring their products are transported safely and securely. With its wide range of advantages, it’s clear to see why this type of plastic is becoming more widely used in the packaging industry each year!